Norm and Daniel Cobb are Suspension Tech International Ltd, a specialist suspension business located at the scenic Lake Ōkareka, just minutes from the famous Whakarewarewa Forest in Rotorua, New Zealand.

Company founder Norm Cobb spent 42 years racing MX and tuning Championship-winning machines. He has extensive knowledge and experience from 40 years in the motorcycle industry. His son Daniel joined the operation in 2018.

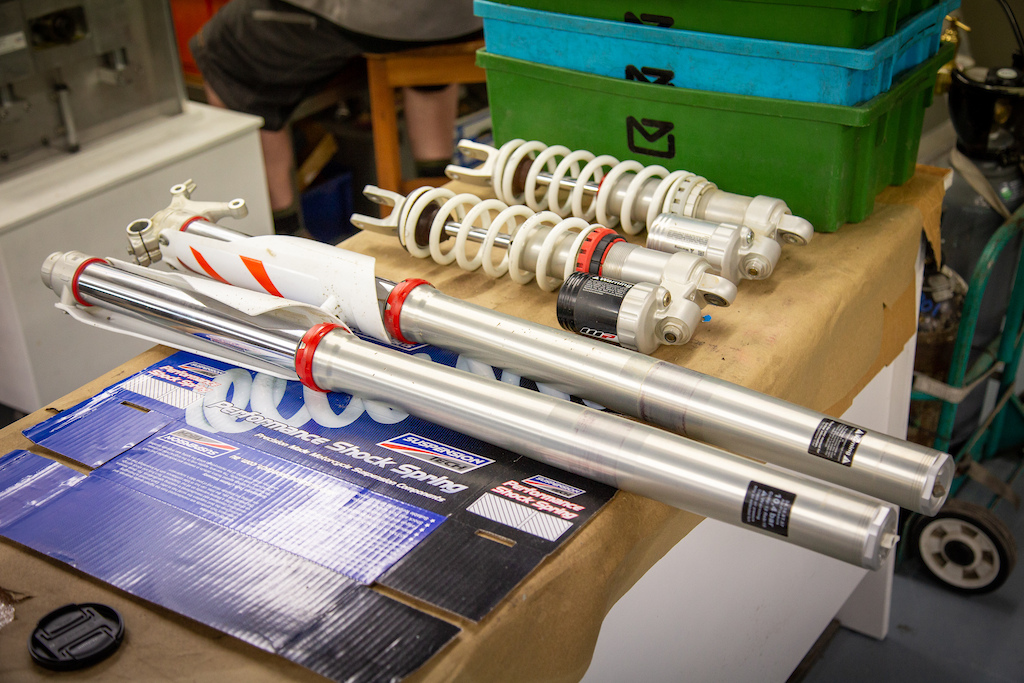

Having worked on and owned many different suspension brands, Norm and Dan became frustrated with many OEM mountain bike shock designs. Shocks were expensive to purchase but suffered constant warranty failures, were overly difficult to service and tune, and often had to be returned to distributors for warranty modifications and upgraded parts.

Together, Norm and Daniel have designed, tested and produced a unique state-of-the-art mountain bike shock that is set for release in late 2023.

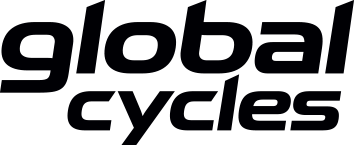

Norm says that the Suspension Tech “Factory A Kit” coil shock is “At last a product for the discerning mountain bike market that is consistent with the exacting standards and performance previously reserved for motocross riders using factory-only components from suspension giants KYB, Showa and WP.”

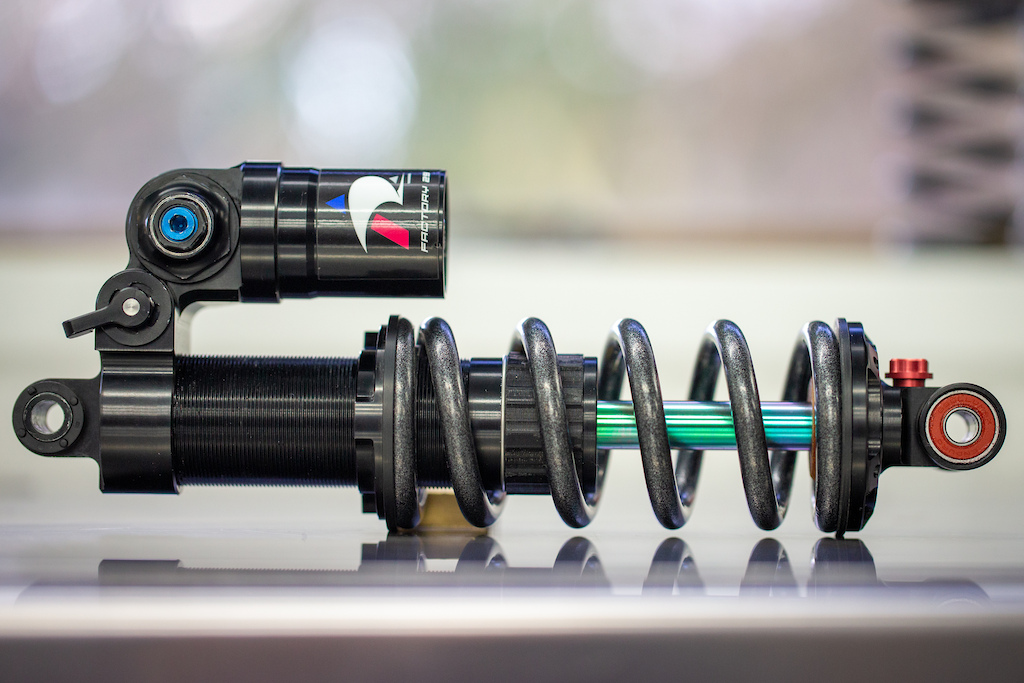

The rainbow green PVD coated shaft is a unique feature. Norm Cobb explains: “Physical Vapour Deposition coating is a process in which a solid material is vaporized in a vacuum and deposited onto the surface of a part. The materials form a thin metal surface layer. This can give the materials completely new characteristics. The production Suspension Tech shocks will feature many different surface treatment options and colours giving customers the option to order a custom shock.”

According to Suspension Tech, all these features, combined with high quality racing shock fluid (instead of fork oil, which they say they often see in mass-produced shocks) results in a shock with almost zero fade and the lowest level of hysteresis seen in any mountain bike shock that is currently on the market.

– 29 mm shock body for larger oil capacity

– 12.5 mm chromium steel shaft that is e-bike rated strength

– Unique PVD coated shaft (applied in the USA)

– Metric 6 mm ID high carbon spring steel shims for consistent tunes

– Parabolic rebound needle for precise rebound metering

– Oil and high pressure nitrogen gas separation via a floating piston reservoir

– All the alloy parts are machined using T6 6061 billet alloy by New Zealand machine shops, then hard anodised to a high penetration level

– Billet cylinder head with compression damping separated into high and low speed adjustments

– Rebound adjuster at the base of the shock shaft in the end eye

– Dual stage compression damping on the main piston for progressive response from small trail chatter to large jumps

– Mono tube damper uses high quality racing shock fluid (not fork oil) unlike many of the current mass produced mountain bike shocks

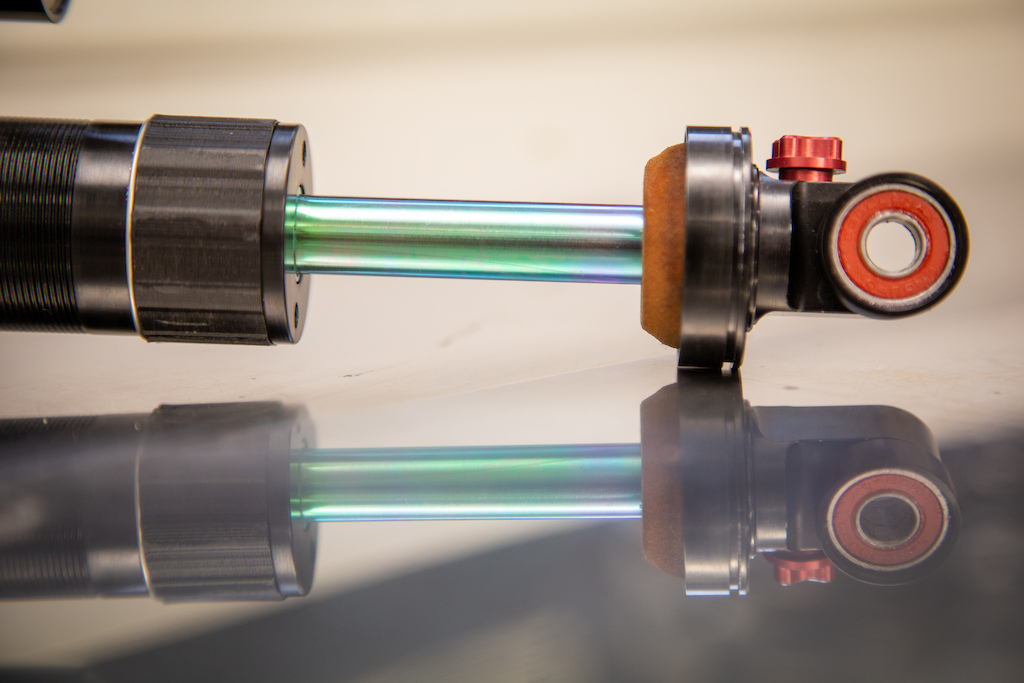

The Suspension Tech “A Kit” shock in 230 x 65 mm weighs 525 grams (without spring). Norm points out that this is 5 grams lighter than a 2023 Fox DHX2 coil shock and that their offering holds almost twice as much oil and has a larger and stronger shaft than most competitors’ high end coil products.

The shock can be reconfigured to fit your next bike by simply changing over mounting and component parts.

Norm says, “I want our customers to keep running this shock without having to buy a new unit just because the new bike has a “trunnion mount” or different length/stroke”. He continues: “We are not seeing anything on the market that is going to make this shock obsolete within the next 10 years, in fact we are now seeing shock designs from the major manufacturers that are more complicated but less durable and harder to tune. This shock is engineered to be quick and easy to tune and maintain without the need for an array of expensive specialised tools.”

Daniel, who is also one of Rotorua’s up and coming enduro racers, was heavily involved in ride testing, research and development. Norm says that his technical input and riding expertise has been a fundamental part of the successful development. Norm is proud that New Zealand Enduro ace Connor Hamilton has had three consecutive local race victories and contested three European rounds of the 2022 EWS using the Suspension Tech A Kit shock.

Ten pre-production test shocks have now been in circulation for the last 14 months. I had the pleasure to ride one of them for a week on a Turbo Levo that a friend lent me and was impressed with the performance, especially considering that it was a prototype and not the product that will be sold. Norm reports that the shocks have endured the months of racing and practise with flying colours.

Future plans also include a “B Kit” shock. This shock will offer the same “A Kit” technology but utilise a polished chrome shaft and black body anodising. It will be more affordable without the expensive premium coatings. Norm’s philosophy is simple – he does not want to produce a cheaper cut-down product that fails to perform. “B Kit” products will retain the capability to upgrade components to “A Kit” specification as a future rider option.

– Made in New Zealand

– Price: TBA

– Weight: 525 g (230 x 65 mm) without spring

– Website: https://www.suspensiontech.com/

– Instagram: @suspensiontechinternational